Two Brothers, Two Careers, One Company by Tracy Weaver, Portland Utilities Construction Co., LLC.

Introduction: In 1995 brothers Mike Woodcock and Greg Woodcock began working at their father Ernie Woodcock’s underground utility company, Portland Utilities Construction Co., specializing in sewer and water pipeline installation. But that’s where their similarities ended. Mike, armed with a Masters’ in Business Administration and a head for numbers, started work as an estimator. Greg, with a young family to support and the ability to make people laugh, hit the highways as a laborer. Listen to their stories and see if underground utility construction is a good fit for you and learn what job openings might best align with your skillset.

PART I GREG WOODCOCK, EDUCATION AND EARLY WORK BEGINNINGS.

In part one of the series, Two Brothers, Two Careers, One Company, Greg Woodcock discusses why college was not for him and his early work at PUCC in the tunnels. Learn why PUCC’s earliest workers in the 1990s came from the Appalachian coalfields, many of whom still work in the underground utility construction industry today.

TW: You had an opportunity to go to college. What did you like or not like about college?

GW: I went to Western Kentucky University for three (3) semesters. The class I really did not like was Basic Design, which was some sort of an art class. I was the only guy in the class. In high school you had to be there so you might as well do the work. In college, there was too much freedom. My thoughts were, “If you didn’t care, I didn’t care.”

TW: What jobs did you do during high school and college?

GW: While in college I delivered pizza. In high school I baled hay, cut tobacco.

TW: What made you decide to become an underground utility construction worker at your dad’s business, Portland Utilities Construction Company?

GW: Early in my life I had kids and I no longer had time to go to college. I had to raise my family. I needed that hourly wage.

TW: What appeal did the sewer and water pipeline industry have for you?

GW: When I was younger, what appealed to me about utility construction was the travelling. I got to see a lot of places.

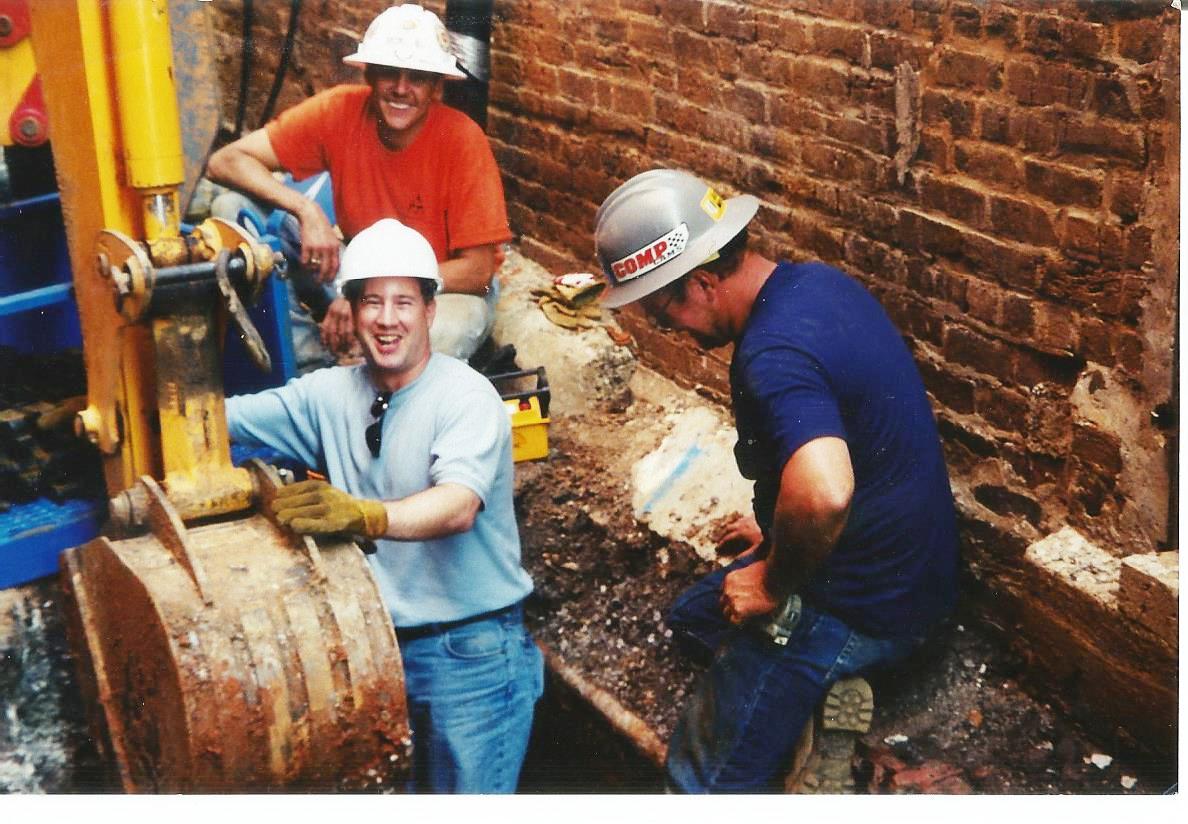

TW: Early on in your career at PUCC you worked as a laborer in the underground tunnels. Tell us about the underground tunnels, what work was involved, how deep did they go and what was their end purpose.

GW: Back in the day we did all open cut sewer pipe. In the 1990s, there was no sewer pipe bursting to follow an existing line. When you open cut a sewer line and came up on interstates, roads or railroads you had to tunnel underneath them. A typical day involved drilling and shooting dynamite in solid rock mostly. Once the air was blown out, we had plywood in the front for the rock to lay down on and a railing system with muck cart. You would shovel the rock into the cart. Next we would take it to the outside, lift it out of the shields with a backhoe, dump it. Repeat process, bring it back down and send it in again. The goal was to install liner plates, one and a half foot wide, four each made a circle diameter. If you got three feet of liner installed in an eight (8) hour day, it was good day.

TW: Tell us about the first crews you worked with for PUCC. What type of people were on the crew?

GW: I started out in the 1990s working in the tunnels around Nashville in Middle Tennessee. It was hard to get anybody to do the work because it looked like the coal mines down there. In Kingsport over in east TN, it was no problem getting people to do the work because they were used to working in the mines.

Today we use trenchless technology like sewer pipe bursting and UV Cured In Place Pipe to install sewer and water pipe and no longer have to rely on tunnel work at Portland Utilities Construction. I believe underground utility construction is a good career choice.

To hear more from Greg about work in the tunnels back in the 1990s, watch this video.

Greg Woodcock, Portland Utilities Construction, Pipe Burst Technician, 1995 to Present. Greg, youngest son of Portland Utilities Construction Co., LLC founder Ernie Woodcock joined PUCC in September of 1995 when he was 25 years’ old. Twenty-five years later Greg continues to be one of the company’s top pipe burst technicians for sewer pipe rehabilitation in the underground utility industry, living and traveling all over the southeast completing company sewer and water rehabilitation projects.